3. RECOMMENDED USE

4. IMPORTANT PLANNING

1) Always install in good lighting so visual defects can clearly be seen and discarded prior to installation.

2) All other construction work should be completed prior to the installation of this product.

3) It is recommended to have an additional box left over after installation, to be used for repairs if needed.

4) For the best overall appearance, select planks from several boxes at a time when installing.

5) A waste factor of at least 5% for cutting is recommended per order. Diagonal installations may require 15% to 20%.

6) Provide a 10mm expansion gap between the walls and floor, all around the perimeter of the floor and around any fixed objects. For areas 15 meters wide or more, a gap of 20mm must be allowed.

7) Areas greater than 15 meters in any one direction must be broken by expansion breaks between planks in the floor, typically at doorways or hallway entrances. These gaps are commonly covered with T-molding.

8) Expansion breaks for 15 meters areas are not required when gluing the flooring planks to the subfloor.

9) The flooring should be glued down in areas with direct sunlight exposure to the floor. In floating applications, windows and sliding glass doors should have proper cover to prevent direct sunlight to the flooring.

10) Recommended adhesives are : Bostik LVT Lock™, GreenGrip and Duragrip, Mapei Ultrabond Eco 962®, and Eco Quicklay spray adhesive.

11) Do not move furniture back onto the flooring until the adhesive has cured.

12) When moving furniture and heavy equipment on the flooring, use luan board, plywood, or other similar covering to protect the floor.

13) Moldings are needed to cover the expansion gaps along the walls, and when the floor edges transition to other floor coverings (carpet, tile, etc.)

14) Hunter AU SPC Hybrid is waterproof. However, in the event of a flood or significant water leaks, the planks should be removed to allow the subfloor to thoroughly dry before reinstalling.

5. CRAWLSPACES

1) If installing over a crawlspace you must have a minimum of 45cm of air space between the ground and floor joist. Crawlspaces should have adequate cross ventilation. The ground of the crawlspace must be completely covered with a minimum 0.15mm or thicker polyethylene moisture barrier.

6. SUBFLOOR

1) Subfloors should be flat within 3mm over a 180cm span, and 5mm over a 300cm span. Sand down high spots, and fill in low spots with a Portland-based floor patch.

2) Wood subfloors must be dry and not exceed 12% moisture content. Test the subfloor moisture in several locations. Readings above 12% on average indicate elevated moisture from water leaks or dampness that needs to be corrected before installation can begin.

3) Screw down loose or squeaky sections of plywood and replace areas that are damaged.

4) The subfloor should be clean and free of protruding fasteners and debris.

7. EXISTING FLOORS

1) This flooring can be floated over existing clean, flat, dry, and well bonded/secured tile flooring, vinyl flooring, and hardwood flooring.

2) This flooring can only be glued down to existing properly prepped flooring that has been approved by the adhesive manufacturer.

3) Do not install this flooring over existing carpet flooring, cushioned vinyl flooring, or existing floating wood and vinyl floors.

8. INSTALLATION TOOLS

1) Tape Measure

2) Wall spacers

3) Pencil

4) Hammer

5) Chalk line

6) Pull bar

7) Table saw

8) Miter saw

9) Jig saw

10) Moisture meter

11) Safety glasses

12) Dust mask

9. UNDERLAYMENT PAD FOR FLOATING INSTALLATIONS

1) Underlayment padding is not required for the installation of this product.

10. FLOATING INSTALLATION

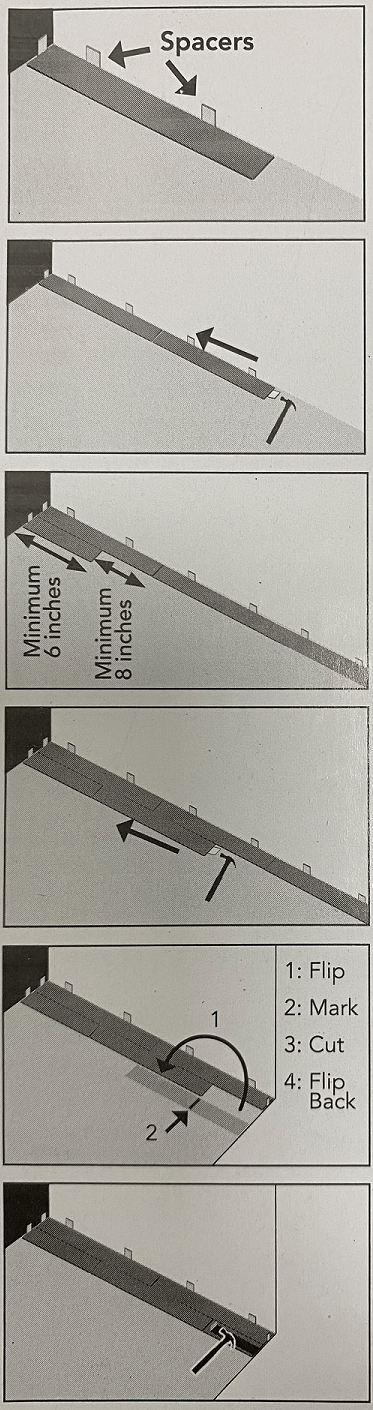

1) Start installing parallel to the longest straightest wall, normally an exterior wall. Install the flooring pieces left to right. The groove side of the plank should be facing away from the starting wall.

2) Using spacers, leave a minimum 10mm expansion gap between the flooring and walls. Don’t skip this important step!

11. LAYING THE FIRST ROW

1) After laying the first plank, lay the second plank in position, and tap it toward the first plank to lock the ends of the boards together. Be sure to use a tapping block so you won’t damage the boards with the hammer. Continue laying boards this way until you reach the other wall.

2) See below for dealing with the last board in the row.

3) See note in PLANNING section about rows longer than 50 feet.

12. LAYING THE SECOND ROW

1) To start the second row, install the first plank, being sure the plank is at least 20cm longer or shorter than the first board in the previous row. There should be a minimum 20cm stagger between any one joint and the nearest joints in adjacent rows. Planks used to start or end a row should be at least 15cm long.

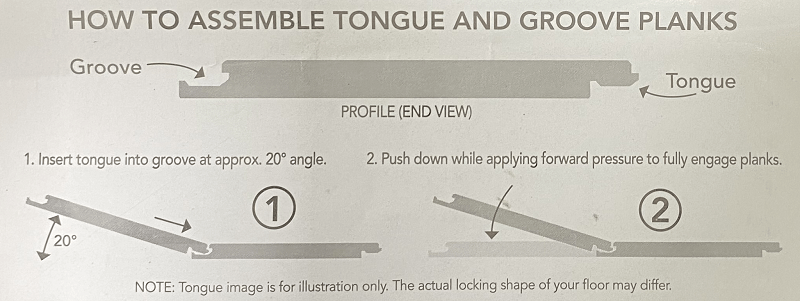

2) Next, install the second plank in the second row by inserting the tongue side into the groove first, then pressing the board down, locking it into the previous row. Then tap the board on its end with a tapping block & hammer to lock it into the previous.

13. CONTINUE

1) Continue installing rows, working left to right, adding additional planks in each row, while maintaining a minimum 20cm stagger between adjacent-row joints.

14. CUTTING END-OF-ROW BOARDS

1) The last board in each row should be cut to fit, while still maintaining a 10mm expansion gap at the wall. Here’s how:

a) Flip the board over (placing the groove to your left.)

b) Measure the board by the gap in the row.

c) Mark and cut the board using a miter or table saw.

d) Then flip the board back over, and it will be ready to insert and be tapped into place.

e) You may use the remaining piece to start the next row.

15. USING A PULL BAR TOOL

1) Use a pull bar to lock in the last plank in any row.

2) Use a pull bar to lock in the last row of flooring being installed in that room.

16. INSTALLING AROUND OBJECTS

1) Use a hole saw drill bit to make perfect cuts for pipes.

2) Use a jamb saw to cut door frames.

3) Use a jig saw for cutting pieces around irregular shapes.

17. AFTER INSTALLATION/FLOOR CARE & MAINTENANCE

1) Sweep up all trash and debris

2) Save extra material and store it in a climate controlled space.

3) Save one box label in case future product is needed for repairs.

4) Install trim to cover expansion gaps, and transitions where the new floor meets other existing areas.

5) Properly protect the flooring before moving furniture back into place.

6) Use felt protectors on furniture legs.

7) Avoid sun exposure to the flooring for long periods. Close blinds and drapes during peak sunlight hours. Excessive heat can cause expansion and warping of the product.

8) Caster wheels should have wide rubber casters. Non-staining, protective mats are required under rolling chairs. Do not use plastic mats, as the eurethane in the mats may bond with the floor.

9) Use walk-off mats at entrances to prevent grit and dirt from being tracked on the floor.

10) Sweep or vacuum the floor regularly. Use a vacuum designed for hard surface floors that does not have a beater bar. Or, the beater bar should be turned off.

11) Do not use polishes, waxes, harsh chemicals or abrasive cleaners on this floor.

12) Wipe up spills immediately with a damp cloth.